Induction Melting Furnace

- We have induction furnace 450 KW medium frequency with 300 kg and 1000 kg crucibles.

- We are able to cast Maximum single piece casting up to 850 kg.

Pattern Shop

- Our pattern shop is equipped with all facilities of rakes and platform for Identification of each pattern in store.

- We mount pattern on match plates for increase life of pattern and increase productivity.

- We are to rectify or repair wooden & aluminium pattern in house.

Methoding For Production

- We have facility of solid works software for paper method cards.

- We use method card of each item, parting line, weight calculation for metal estimation, metal solidification pattern, use of exothermic sleeves, use of chills, etc

- Our 22+ years of Rich experience in Methods department of Steel casting foundry gives an EDGE in methoding of casting that leads to production of Sound Quality Castings.

Moulding And Core Preparation

- We have CO2 Single Arm Continues Mixer with capacity of 8ton per day

- We have 2 no. Sand Batch mixture, 2 no.Sand muller and Sand Reclamation Plant etc.

- We are using CO2 process for moulding and core are paper by Nobake casting process.

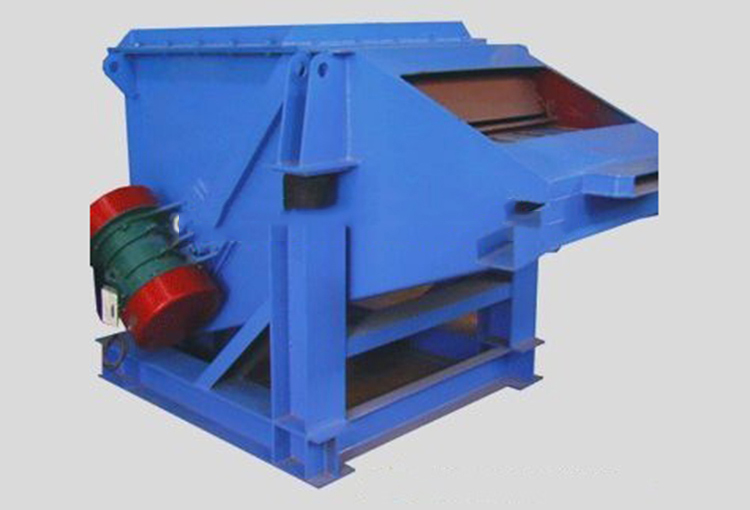

Shot Blasting

- We have facilities of hanger type Shot Blasting Machine – Capacity 1 Ton single piece.

Heat Treatment

- We have oil fired Heat Treatment Furnace of for Normalizing, Solution annealing, Tempering, Quenching, Precipitation hardening and Post Weld Heat Treatment etc.

- The capacity of Heat Treatment Furnace is 3MT with PLC controls for controlling of rate of heating, Soaking Temperature & Time.

- The HT furnace is connected with PC for records Temperature & Time and converts the same process in heat Treatment chart.

Fettling and finishing

- Our Fettling shop is equipped with all facilities 2no Swing frame grinders, 3 no Welding machines, 7 no. flexible Grindings, Arc cutting & gouzing machine, cutting machine etc.